Grease Separator

Greasly - a part of the Modern Kitchen

A typical application of a grease separator is the treatment of wastewater containing fat and grease from hotels, restaurants, cafeterias and other catering or food processing operations. GREASLY will, by the removal of fat and grease, greatly reduce incidents of blocked drains and prevent contamination of sewage treatment plants.

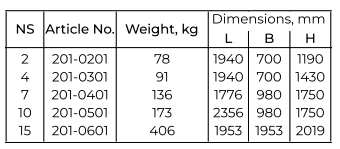

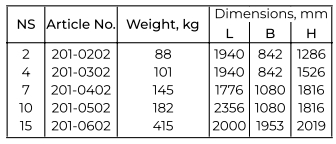

ENEKA offers Free-standing Greasly-A and Underground Greasly-B grease separator models. The body of the separator made of polyethylene material are durable, corrosion-proof and chemically resistant, light and easy to transport.

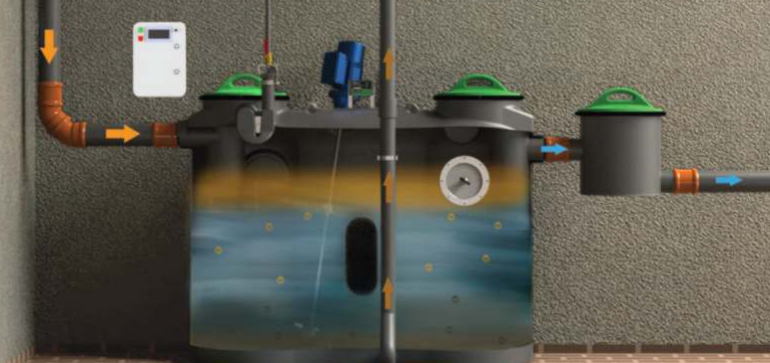

Optimal grease separation

Incoming greasy wastewater enters the grease separator through a unique inlet module which creates the circular flow path. As water passes through the separator, grease particles, lighter than water, are driven upwards by gravity and accumulated in the collection area on the water surface. At the same time, solids and other impurities heavier than water settle to sludge trap at the bottom of the tank. Treated water is discharged through the outlet pipe.

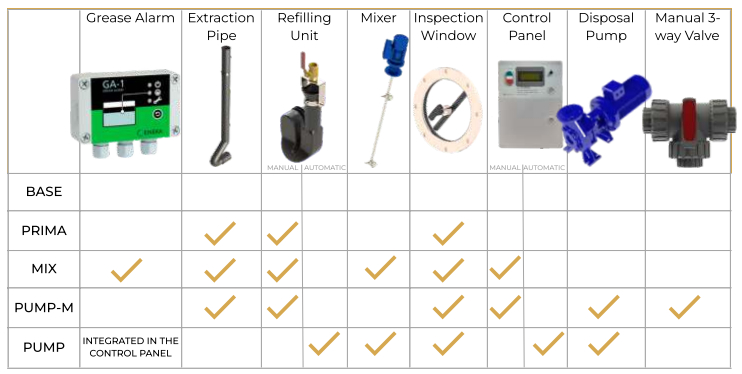

Our Model

We provide approved and certified fire application doors for commercial spaces. These doors come with fire-rated hinges, a latching device, and a sound closing system.

prima model provides odour-free operation without the need for opening of the cover. The accumulated grease layer can be observed through the Inspection window. After reaching the maximum level of grease the contaminants are disposed of through the extraction pipe by a vacuum truck.

After complete disposal, the separator is filled up with fresh water via the refilling unit by opening the manual ball valve.

MIX model is equipped with a grease alarm which is indicating when the maximum level of accumulated grease is reached. Before emptying, mixer actuated for blending grease, water and solid layers thus facilitating the disposal of the separator. The extraction pipe is provided for the emptying by the vacuum truck. After complete disposal, the separator is filled up with fresh water via the refilling unit by opening the manual ball valve.

prima model provides odour-free operation without the need for opening of the cover. The accumulated grease layer can be observed through the Inspection window. After reaching the maximum level of grease the contaminants are disposed of through the extraction pipe by a vacuum truck.

After complete disposal, the separator is filled up with fresh water via the refilling unit by opening the manual ball valve.

PUMP model is equipped with an autonomous program-controlled emptying system including a disposal pump, a mixer and a grease alarm (integrated in the control panel). A grease alarm is indicating when the maximum level of accumulated grease is reached. The operator activates the automatic disposal mode on the control panel or remote controller(optional). First of all, the mixer is turned on for blending grease, water and solids. Then the disposal pump is actuated for emptying of the separator.

After complete disposal, the separator can be rinsed by freshwater which is illed through the refilling unit, mixed and emptied by the disposal pump. After rinsing, the separator is filled up completely with fresh water.

Accessories